Products display

We are a professional automotive lighting equipment manufacturing plant established in 2017.

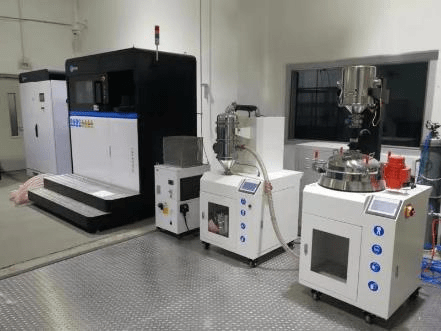

Equipment

High-precision automotive lighting injection molding machine-Specially designed for the customized production of LED car light housings and covers, featuring automated injection molding, high-precision temperature control, and mold adaptation capabilities.

Lighting heat treatment equipment-Automotive headlight heat treatment equipment: precise temperature control, enhancing the strength and toughness of the headlight body.

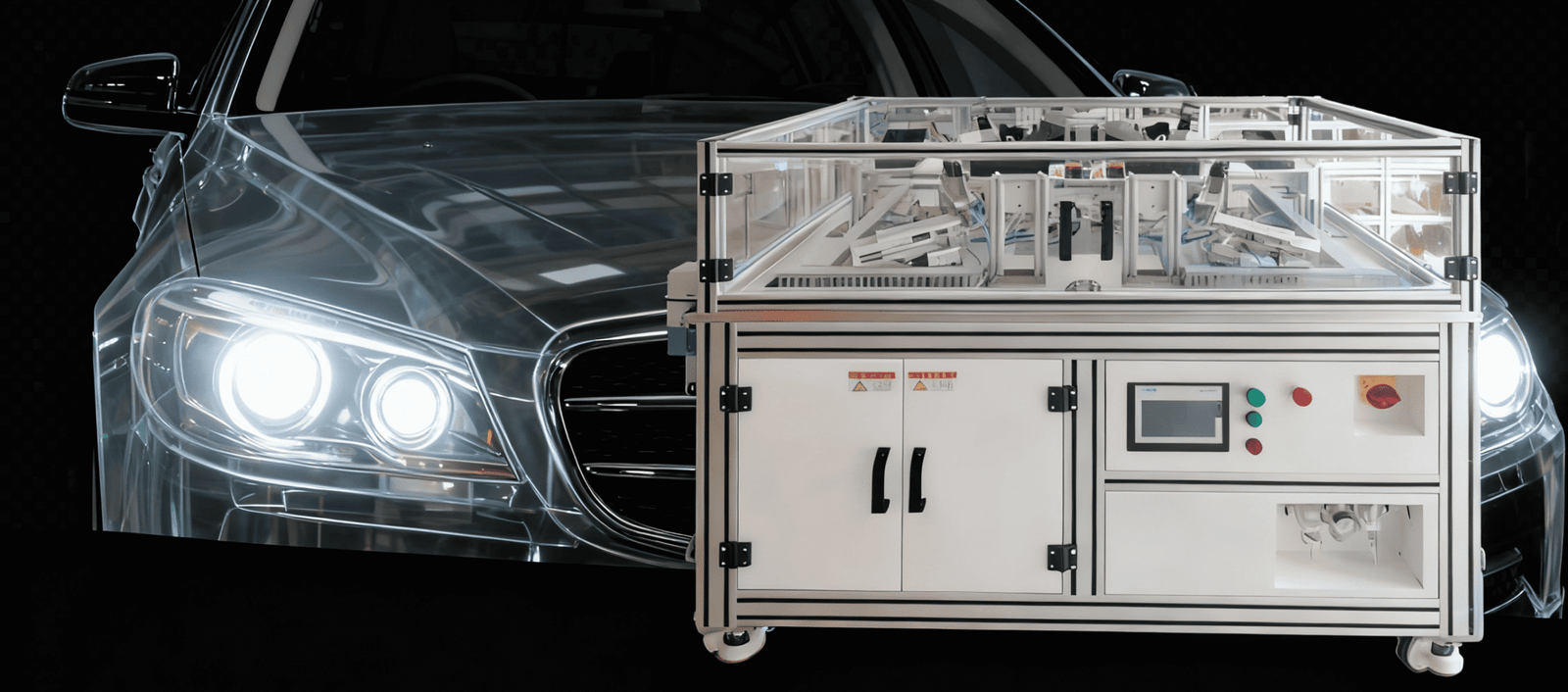

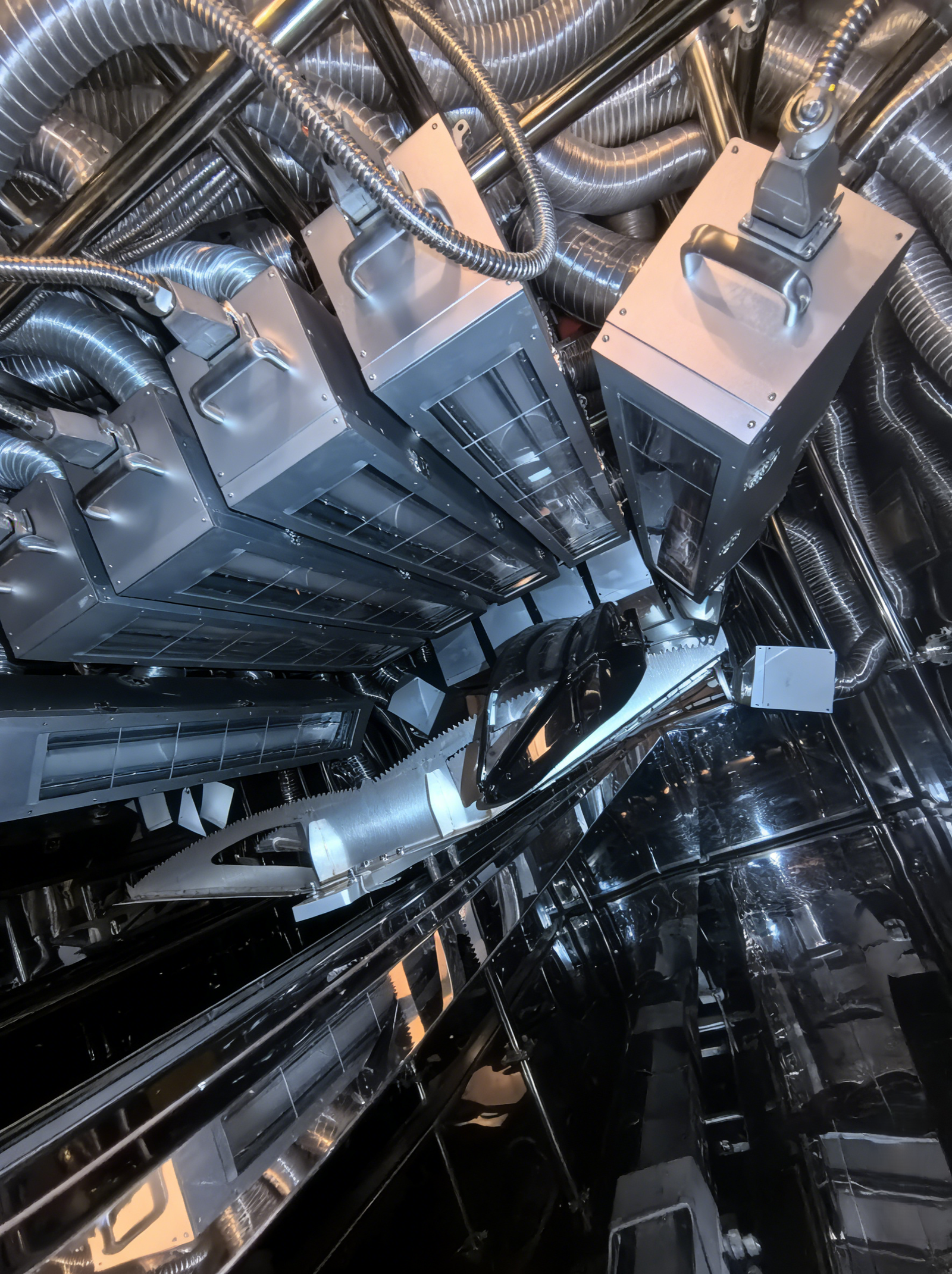

Automotive Lighting UV Curing Production Line-– fast curing, precise bonding, eco-friendly. Optimized for car lamp manufacturing, compatible with various materials. Boosts productivity, ensures stable quality.

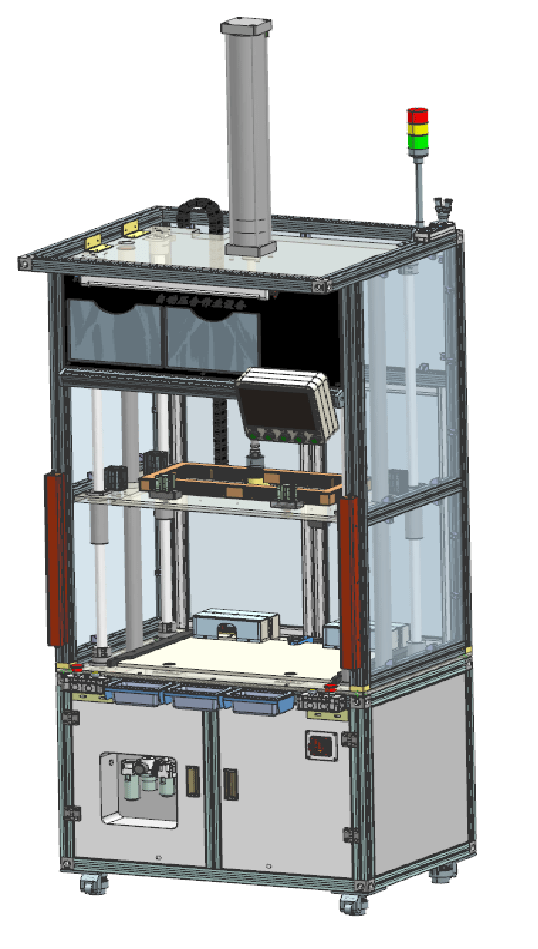

Automatic locking device-High-precision automated locking and fastening, adaptable to various vehicle models’ headlight assembly, precise positioning reduces errors, improves assembly efficiency by 30%, and offers customized solutions.

Hot riveting equipment-Precision hot riveting ensures reliable automotive light assembly.

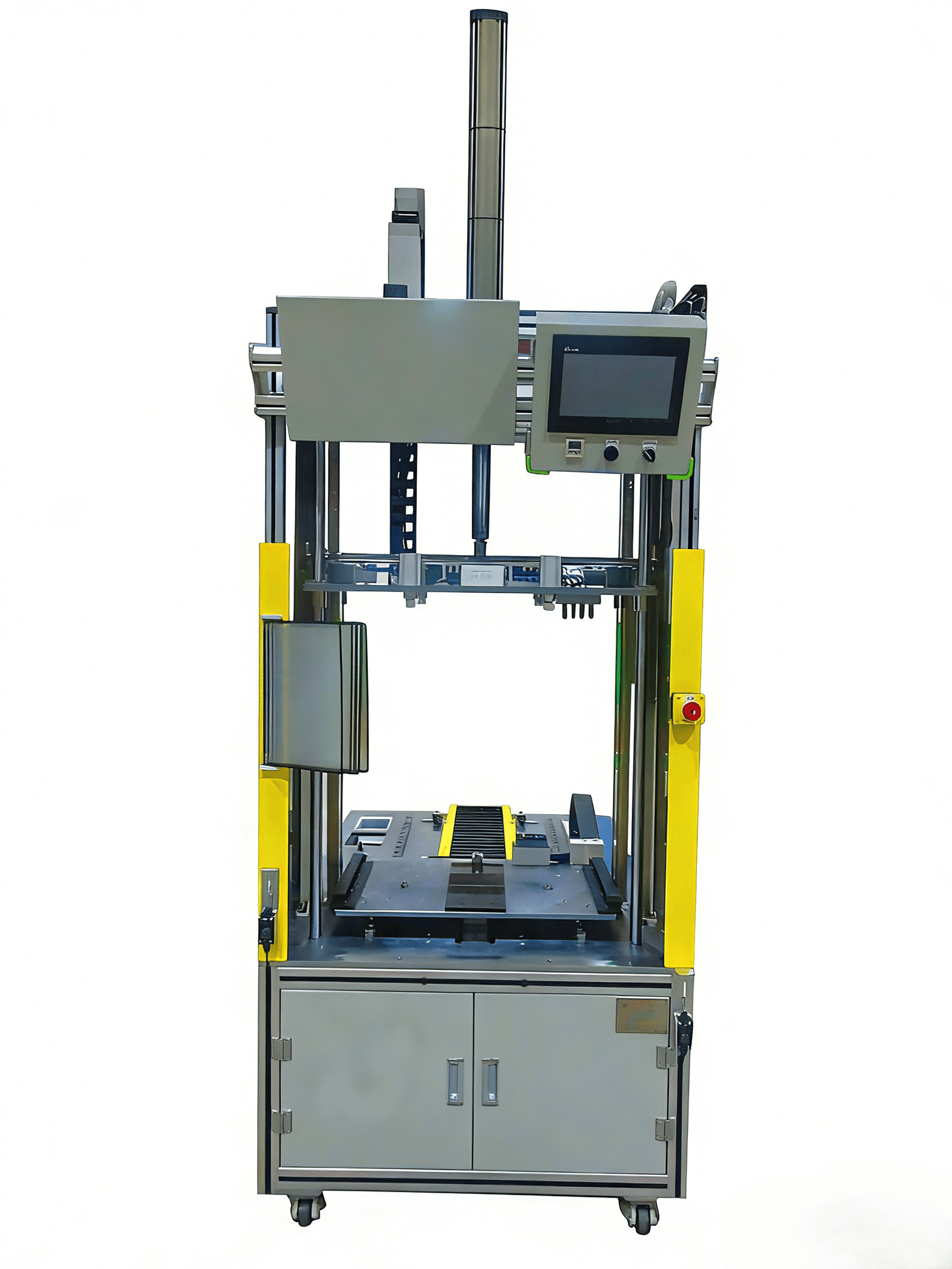

Laminating equipment-Specialized equipment enables precise pressing of the lampshade and lamp housing.

Assembly equipment-Integrated equipment enables automated assembly of automotive lighting fixtures.

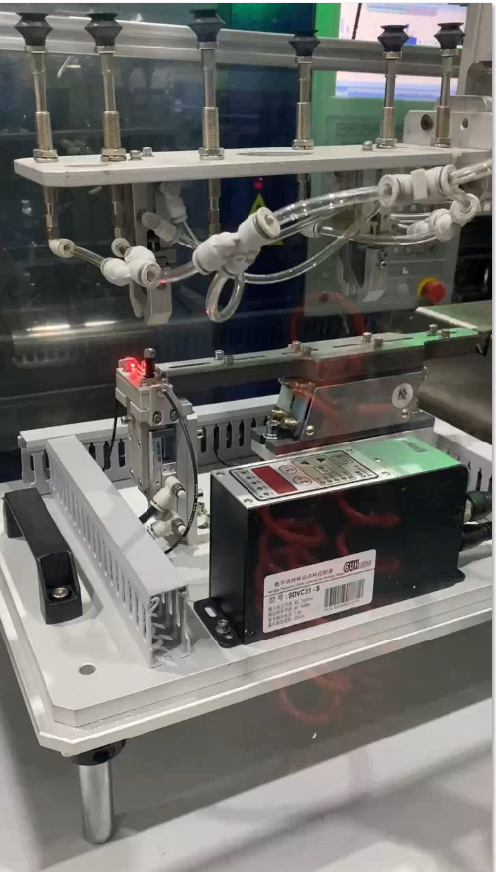

Testing equipment-Precise testing of all performance parameters ensures reliable lighting quality.

Headlight and fog light equipment-Precision-controlled front fog lights, high-quality automotive lighting for equipment protection.

Long taillight equipment-professional equipment, efficiently manufacturing high-quality automotive lighting components

Tail light equipment-Professional taillight equipment, creating exquisite automotive lights.

Lighting heat treatment equipment-Automotive headlight heat treatment equipment: precise temperature control, enhancing the strength and toughness of the headlight body.

Other product

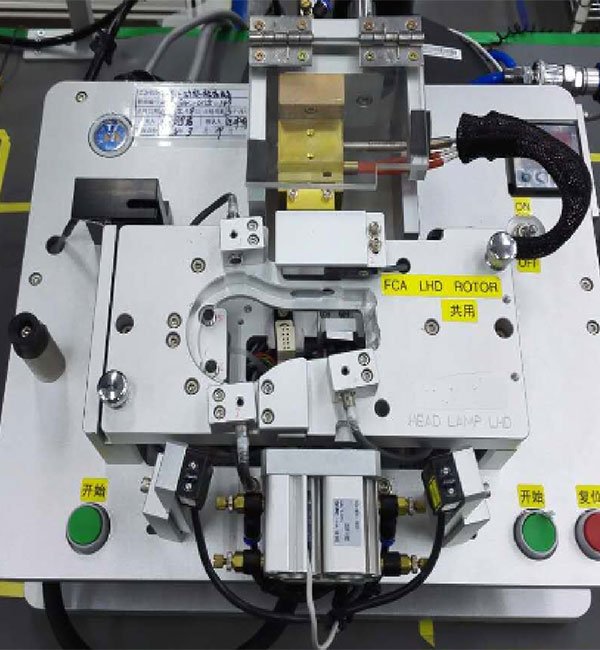

Tooling fixture-Various specialized tooling fixtures ensure the precise positioning and assembly of lighting components.

Headlight leveling motor -Auto-adjusts beam height, preventing glare for safe driving.

LED Headlights–

LED headlights deliver superior visibility, energy efficiency and durability, enhancing driving safety.

LED light mounting bracket kit-Accessories for securing and mounting LED searchlights and light strips on off-road vehicles, trucks, and other vehicles.

Featured products

We are establishing an industrial equipment and parts customization center.

About Us

10 +

years of

experience

Xuzhou Langqi Machinery Technology Co., Ltd., established in 2017, specializes in the research and development and production of automotive lighting manufacturing equipment/production lines and related components. The company’s main products include automotive lighting production lines, automotive lighting production equipment, tooling fixtures, and leveling motors、headlight、taillight and LED light mounting bracket kits, etc. The company is committed to providing high-performance, customizable one-stop solutions to global customers.

News center

Xuzhou Langqi Machinery Technology Co., Ltd. is a high-tech enterprise established in 2017 integrating R & D and production.

Interior FAQs

What are the core molding equipment for auto lighting production, and what are the key selection criteria?

The core molding equipment for auto lighting production is high-precision injection molding machines, matched with professional optical molds for shaping key plastic components such as lamp covers, lamp housings, and reflectors.When selecting this equipment, the following key criteria must be considered:Material adaptability,Precision control,Production efficiency ,Energy efficiency and stability.

What equipment is needed for testing the optical performance of automotive LED lights?

Testing the optical performance of automotive LED lights requires professional equipment such as goniophotometers, integrating spheres, and optical measurement software. These devices mainly test core indicators such as light distribution, luminous intensity, color temperature, color rendering index (CRI), and light transmittance.

What automated equipment is essential for automotive lighting assembly lines?

Essential automated equipment for automotive lighting assembly lines includes robotic arms for assembly, automatic dispensing machines, laser welding machines, and automated testing stations.

What types of auto lighting production equipment can your company provide, and can it meet the customization needs of different customers?

We provide full-process equipment covering molding (injection molding machines, molds), assembly (robotic arms, dispensing machines), testing (goniophotometers), and waterproofing (IPX7 test chambers), suitable for traditional LED and high-end ADB/DLP lights. We offer customized solutions: integrated lines for new energy vehicle high-value lamps, cost-effective semi-automatic combinations for SMEs. With global customer service experience, we accurately match regional technical standards.